Discover the Superiority of Central Steels Casing Pipes

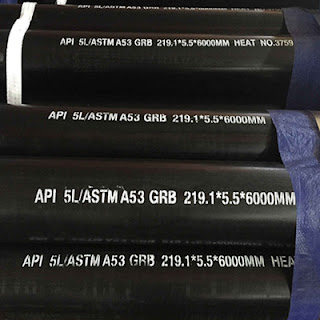

Are you looking for top-quality casing pipes for your construction project? Look no further than Central Steels! Our central-steels casing pipes are known for their exceptional durability, strength, and reliability. Let's dive into the world of casing pipes and explore why Central Steels is the best choice for your construction needs. What are Casing Pipes? Casing pipes are essential components used in various construction projects, especially in the oil and gas industry. They are designed to protect and support the walls of a borehole during drilling operations. Casing pipes also prevent the collapse of the borehole walls and help control the flow of fluids in the well. Why Choose Central Steels Casing Pipes? Central Steels offers a wide range of high-quality casing pipes that are manufactured to meet the highest industry standards. Our casing pipes are designed to withstand extreme conditions, including high pressure, temperature, and corrosion. Whether you are drilling in