Exploring the Significance and Applications of Seamless Pipes

Seamless pipes, an integral component of various industries, play a crucial role in facilitating the transportation of fluids and gases under extreme conditions. Renowned for their durability, strength, and reliability, seamless pipes offer distinct advantages over welded pipes, making them indispensable in sectors ranging from oil and gas to automotive and construction.

Understanding

Seamless Pipes

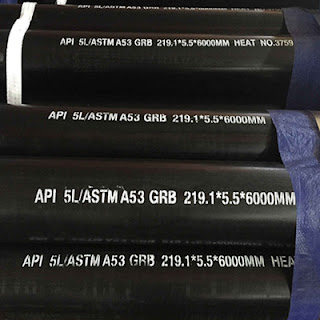

Seamless pipes are cylindrical tubes manufactured without any welding joints or seams. They are typically produced from solid cylindrical steel billets through a process known as extrusion or rotary piercing. This method ensures a homogeneous structure and uniformity in wall thickness, enhancing the mechanical properties and performance of the pipes.

Advantages of

Seamless Pipes

Strength and Durability: Seamless pipes exhibit superior strength and durability compared to welded pipes, making them suitable for high-pressure and high-temperature applications. Their uniform composition and absence of weld seams eliminate weak points, reducing the risk of leakage and structural failure.

Corrosion Resistance: Seamless pipes are often made from corrosion-resistant materials such as stainless steel, alloy steel, and carbon steel, offering excellent resistance to chemical corrosion, oxidation, and erosion. This property prolongs the lifespan of the pipes and ensures reliable performance in corrosive environments.

Smooth Internal Surface: The seamless manufacturing process results in a smooth internal surface finish, minimizing frictional resistance and pressure drop during fluid flow. This characteristic is particularly advantageous in applications requiring efficient fluid transportation, such as oil and gas pipelines and hydraulic systems.

Precision Dimensional Tolerance: Seamless pipes are manufactured to precise dimensional tolerances, ensuring uniformity in diameter, wall thickness, and length. This level of accuracy allows for seamless integration into complex systems and facilitates ease of installation and maintenance

Comments

Post a Comment